"Reinforced concrete slab for covering industrial areas enterprises and enterprises of maritime transport"

As part of the development of Working documentation for the construction of the facility "Construction of a site for storing containers (1st and 2nd stages) within the framework of the project" Construction of the first stage (hydraulic structures) of a container terminal at Karantinny mole SE "Odessa Sea Trade Port" at the expense of artificial formed territory "our company has developed and registered in the register of DSTU (TU-U-23.6-41239326: 2017) a unique development:" Reinforced concrete slab for covering the territories of industrial enterprises and marine transport enterprises "

The basis for the creation of this slab is the task of creating a durable, high-quality in operation, maximum repairable, as well as an easy-to-use coating for the territories of industrial enterprises and marine transport enterprises.

This slab is intended as the main covering element for areas where storage of sufficiently large stacks of cargo is envisaged, which provides for the transfer of significant loads to the base.

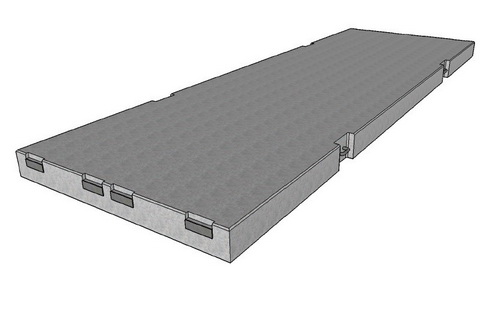

The slab has dimensions of 6x2x0.22 meters and is manufactured using prestressed reinforcement А800С.

The maximum load from the stored cargo for the use of such a plate is 25 t / m2 with a base elastic modulus of not more than 45 MPa, or in the case of storage of containers up to 37.2 tons of point load, which corresponds to the load from

containers stored in five tiers, taking into account the design coefficients.

For the manufacture of this slab, concrete B30, F200, W8 is used, on sulfate-resistant Portland cement.

The plate has passed all the necessary tests, which is confirmed by the test certificates.

The maximum load on the slab applied during the tests was about 38 tons.

3-D plate model

Photo materials of plate tests

Use of slabs at the facility "Construction of a site for storing containers (1st and 2nd stages) within the framework of the project" Construction of the first stage (hydrotechnical structures) of a container terminal at the Quarantine jetty of the State Enterprise "Odessa Sea Trade Port" at the expense of an artificially formed territory "

Compared to other types of coating that are most often used on the territories of industrial enterprises and marine transport enterprises, namely FEM slabs 12 cm thick, and ordinary reinforced concrete slabs, this slab has a number of significant advantages.

Regarding the coating made of FEM slabs 12 cm thick, the coating using 6x2x0.22 meter plates made using prestressed reinforcement is more reliable in case of possible subsidence of the base soil, is more repairable and does not require temporary decommissioning of a significant part of the storage site during the time to rewire the web, requires less labor for installation, and also for the envisaged long-term operation is a more economical technical solution than a coating of FEM plates with a thickness of 12 cm.

As an example, a reinforced concrete slab 3.5x3.5x0.35 meters was taken for analysis. This slab is also characterized by the possibility of using it in areas with rather heavy loads from the stored goods.

Plates 3.5x3.5x0.35 meters relative to plates 6x2x0.22 meters, made using prestressed reinforcement, have a number of disadvantages:

- 6x2x0.22 slabs have a mass of 6.6 tons, while 3x3.5x0.35 slabs have a mass of about 10 tons, which makes 6x2x0.22 slabs easier to install, which also have an advantage in transportation due to their lower mass;

- when using 6x2x0.22 slabs, savings of reinforcement and concrete are achieved in relation to the use of 3x3.5x0.35 slabs;

- in the event of subsidence, the current repair of the base when using plates of a larger area is easier, faster and more efficient;

- when using prestressed reinforcement, the adopted slabs have a lower susceptibility to chips and cracking due to a more even distribution of the load;

- 6x2x0.22 slabs more evenly distribute the load from the stored cargo to the base, and thereby reduce the possibility and likelihood of subsidence.

This product is a patented intellectual property of MARIN PROJECT INTERNATIONAL LLC.